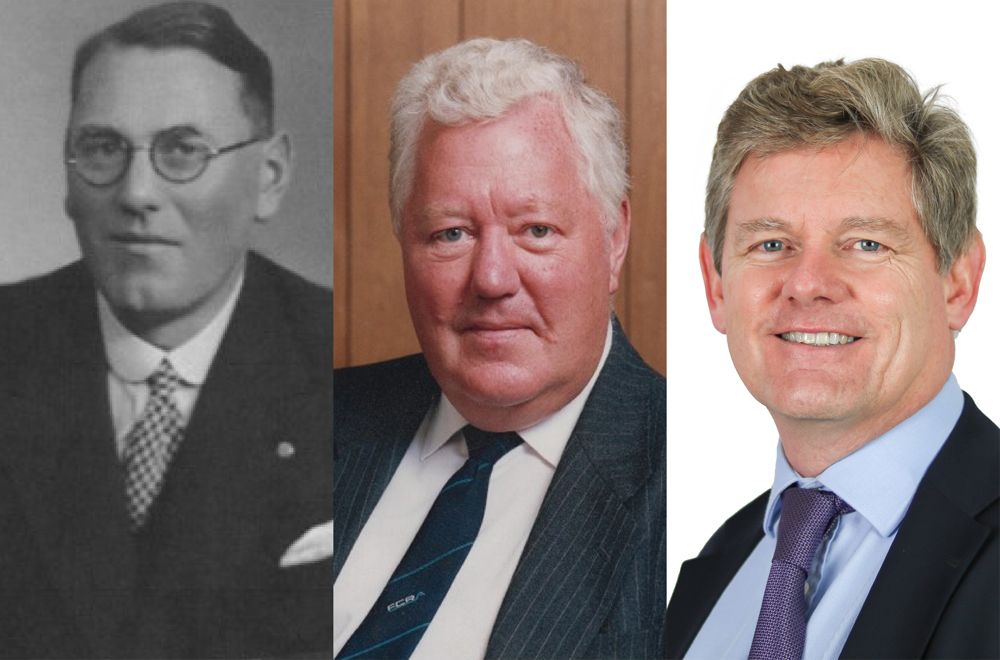

Fry Family | Cedric Fry, Donovan Fry, Simon Fry

Micronclean has been owned and managed by Fry family since the 1920’s and throughout our history, we have focused on quality, innovation, attention to detail and customer care. These attributes have been formalised into the SKIEs programme which covers Stewardship, Knowledge, Innovation and Excellence. The SKIE's attributes provide a compass for our strategic direction, help inform the multitude of day-to-day business decisions and keep our customers firmly at the centre of everything we do.

Micronclean employs over 400 people across the UK with most of these being based at our three main production sites in Lincolnshire. We have an active Continuous Improvement programme driving business improvement for our customers.

Looking to the future, we are confident of growth not only in the UK but also in export markets as we seek to leverage not only our laundered garment and mopping service, but also consumables sales. Our unique in depth laundry knowledge delivers business opportunities in overseas markets in line with our mission statement