Big Blue Blog - Labelling, Packaging and Presentation

BlogCleanroom10.03.2022

BlogCleanroom10.03.2022

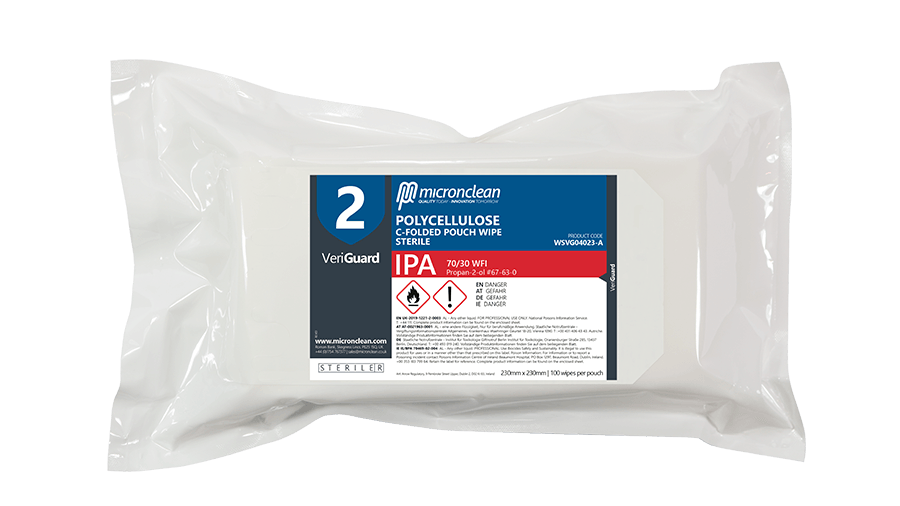

Single use items such as wipes or disposable garments are not usually individually marked and the product packaging provides all relevant information.

Reusable items which undergo repeated use and cleanroom decontamination cycles are individually labelled.

Labelling of cleanroom items is required for various purposes;

- To individually identify the item.

- To track the location of the item.

- To monitor the process count of re-cycled items.

- To provide process and expiry date information.

- To visually identify sterilised items.

- To identify items with user-specific information.

- To meet corporate identity requirements.

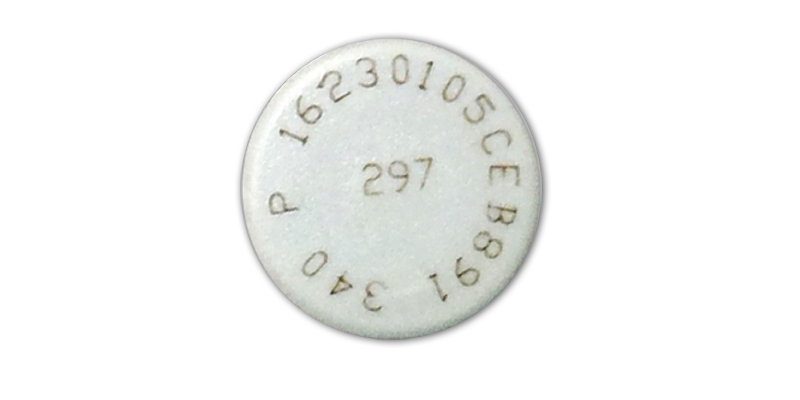

Each individual item is identified with either a barcode or a transponder which can be read at any point by a suitable electronic reader.

Information gathered in this way can be managed in a database to provide information such as location, number of process cycles and number of sterilisation cycles.

In order to identify the item visually, printed labels are produced which may be sewn onto the fabric or sealed on with adhesive.

Direct printing onto the fabric can be achieved using sublimatic ink transfer and this allows the application of any design or colour and is especially effective for the application of corporate logos or to provide information such as department of use.

Process labels, such as process batch number, expiry date and sterilisation indicator labels (detex labels), are normally applied to the primary packaging and are clearly visible at the final point of use.

Packaging and presentation

The packaging and presentation of cleanroom decontaminated products is dependent on the type of product and the cleanroom in which it will be used.

Primary packaging is product specific, for example;

- Sterile alcohol-impregnated cleanroom wipes require primary packaging which will completely contain the alcohol impregnant and be physically strong enough to contain the wipes but also allow easy access to the contents. It must remain unchanged by gamma irradiation or VHP gassing, be effectively cleaned by wiping and readily accept product labels.

- Cleanroom clothing for low classification areas requires primary packaging which will contain the garment and provide a protective barrier to prevent re-contamination. It may need to be cleaned by wiping with alcohol and will need to accept process labels. The material needs to be transparent to allow the clothing and its labels to be visible to the wearer and must be easy to open.

Secondary packaging consists of additional layers which can be removed in stages when the product is being used and for high grade cleanroom operations up to 4 packaging layers may be required.

Presentation of cleanroom clothing and consumable products can also be tailored to individual needs. For example specific folding of garments may be needed to match prescribed and validated gowning procedures or a variation on the number and type of packaged cleanroom wipes or mops may be requested by the end user.