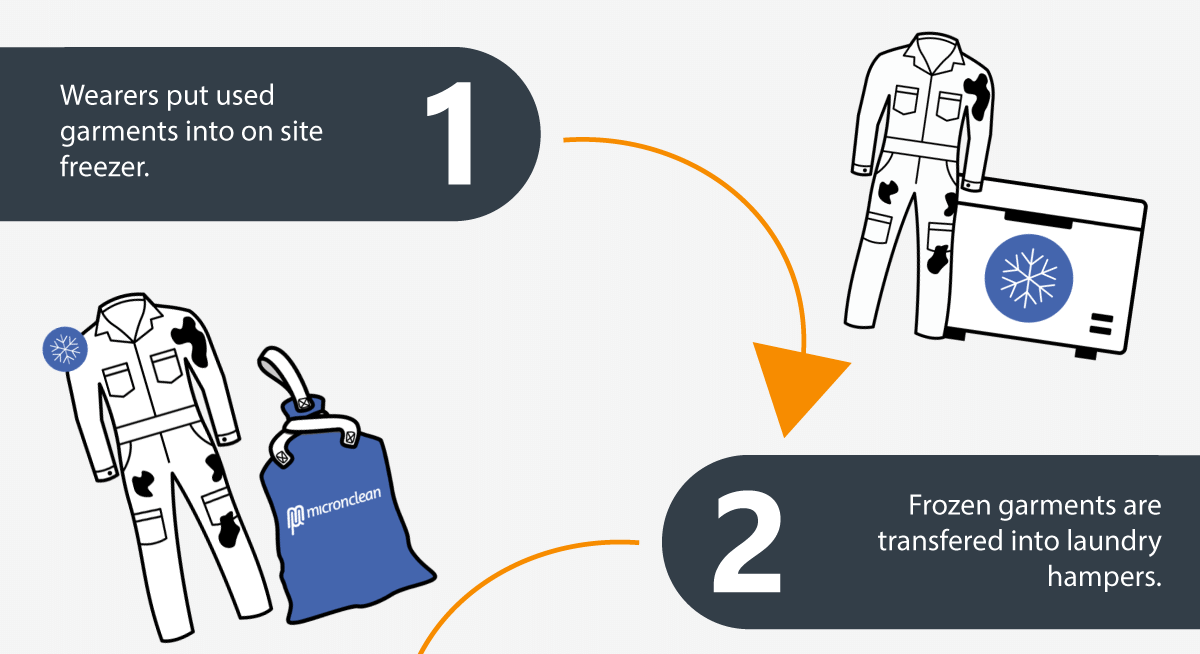

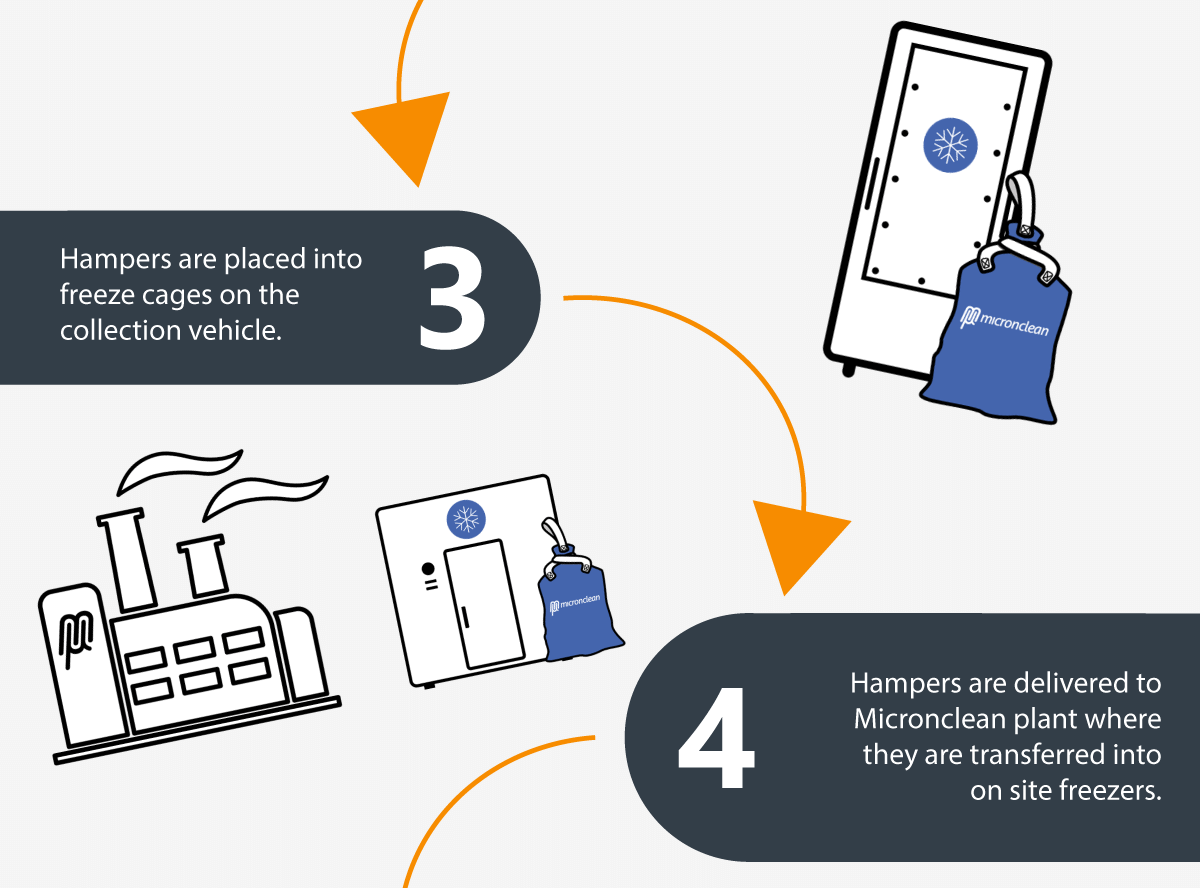

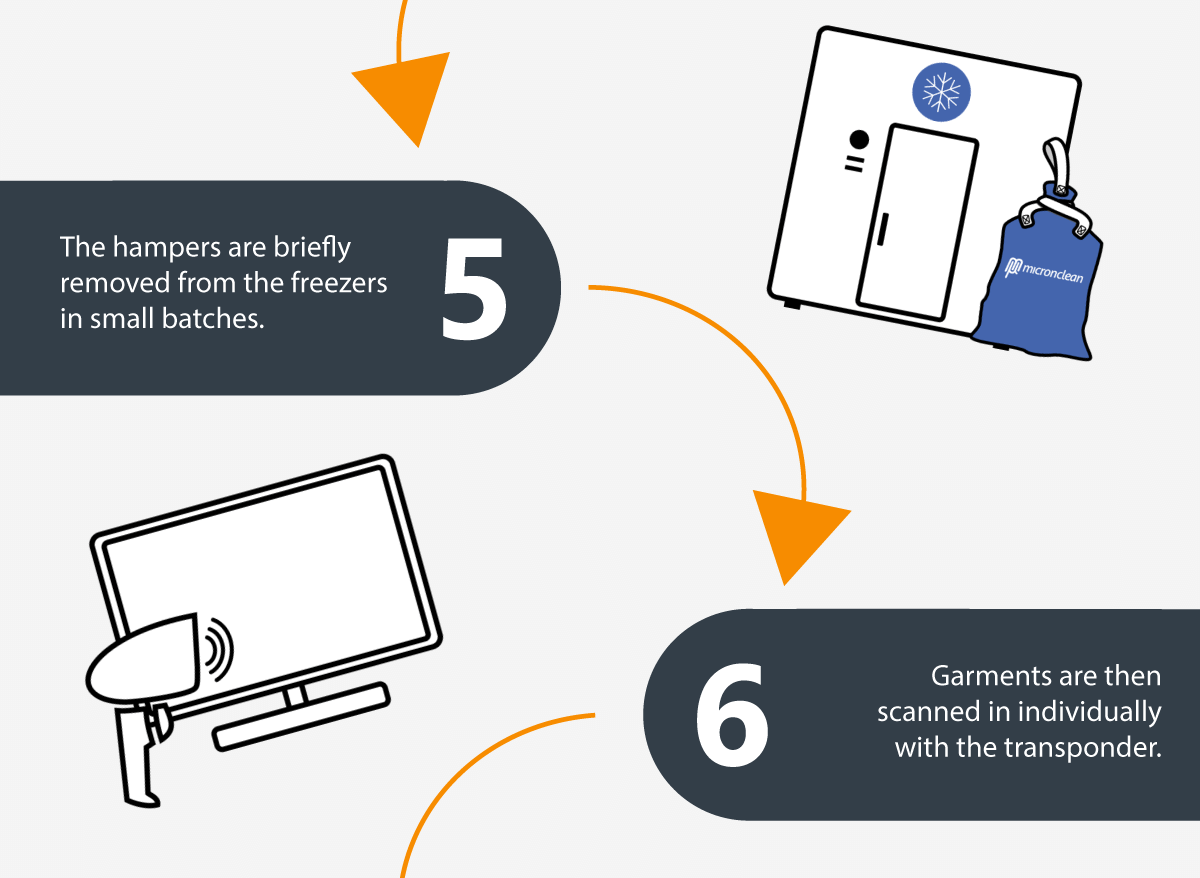

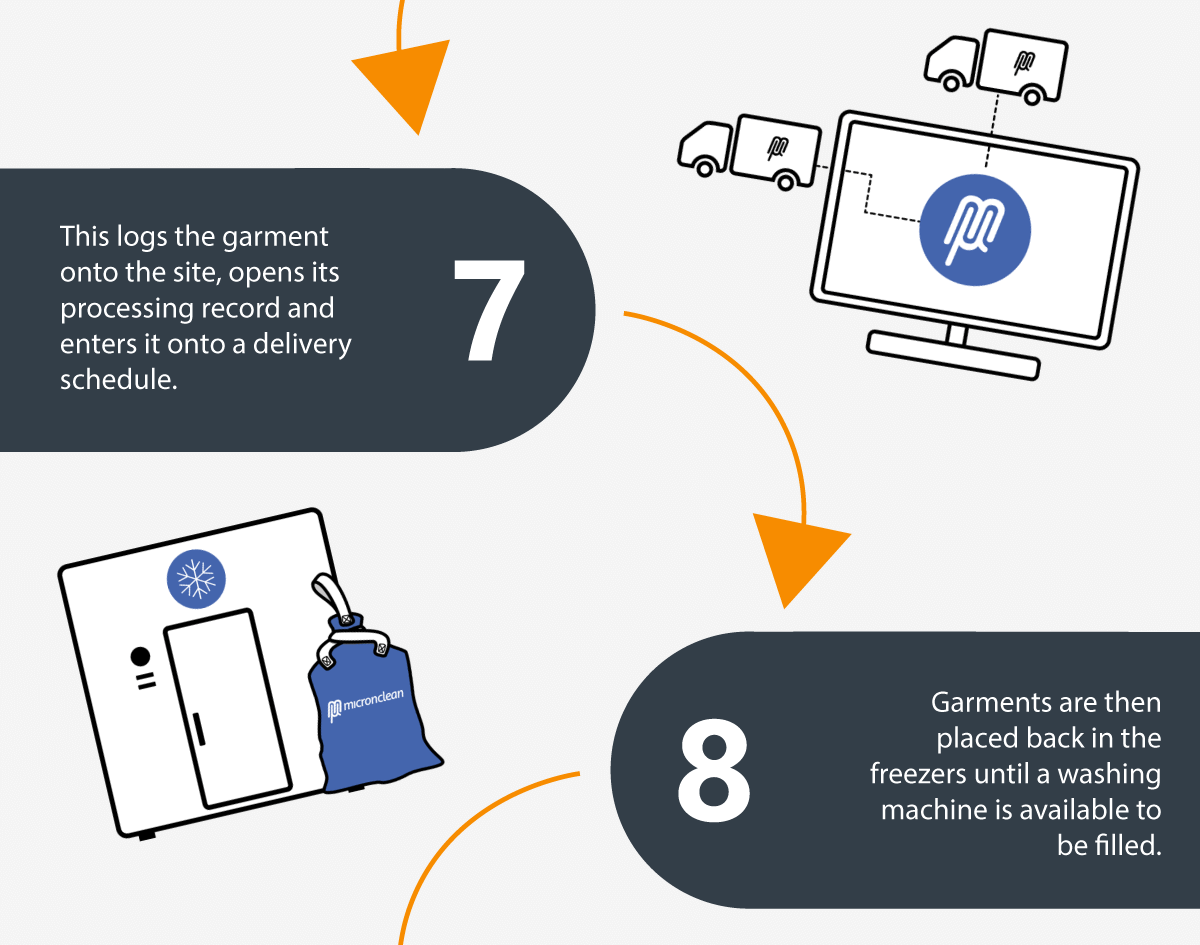

Paint Shop Garments - Process Flow

BlogPPE/Textiles02.08.2022

BlogPPE/Textiles02.08.2022

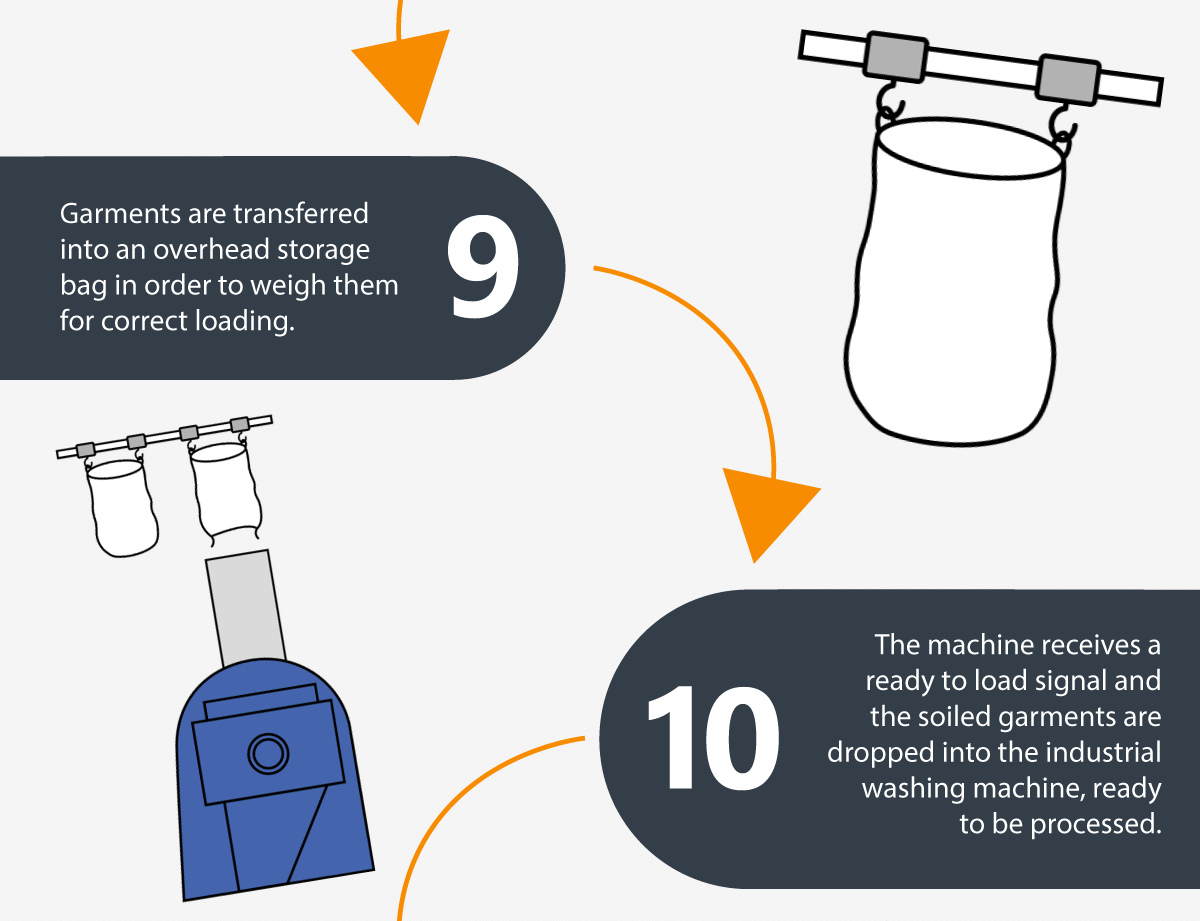

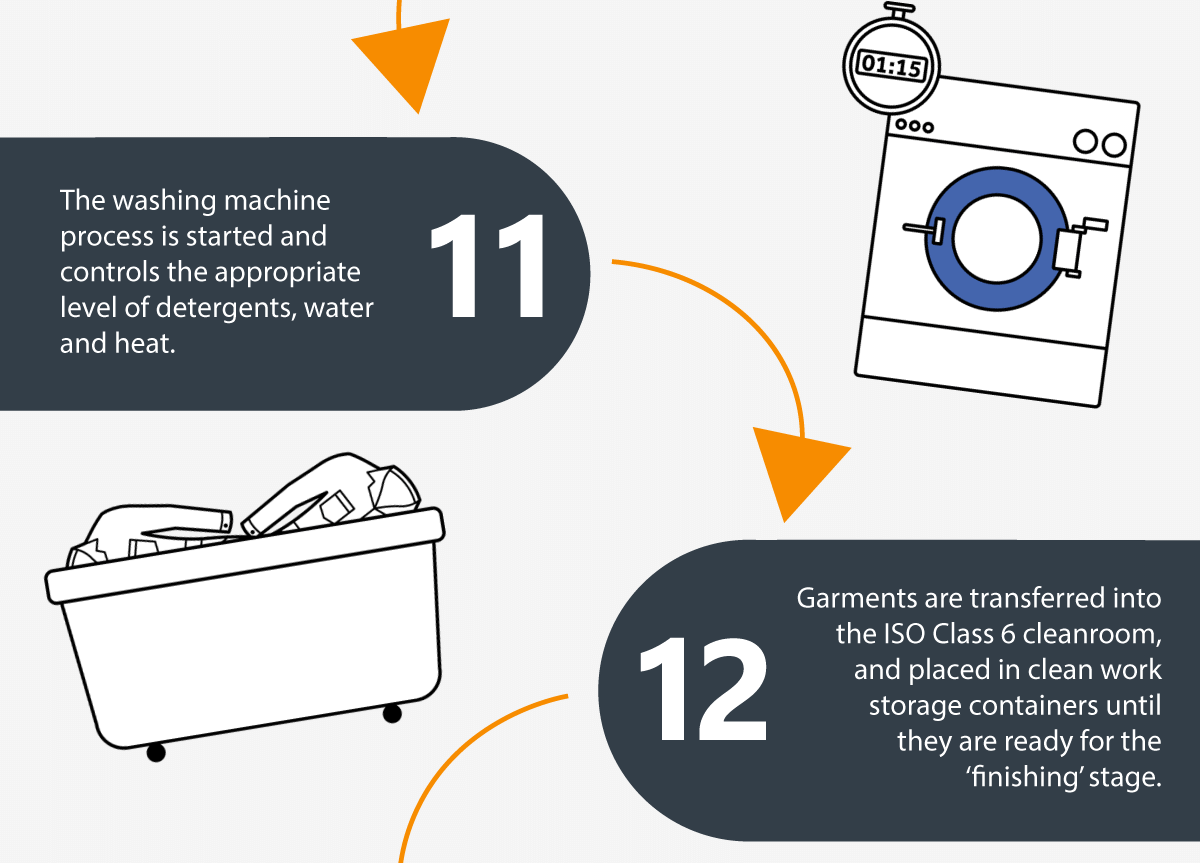

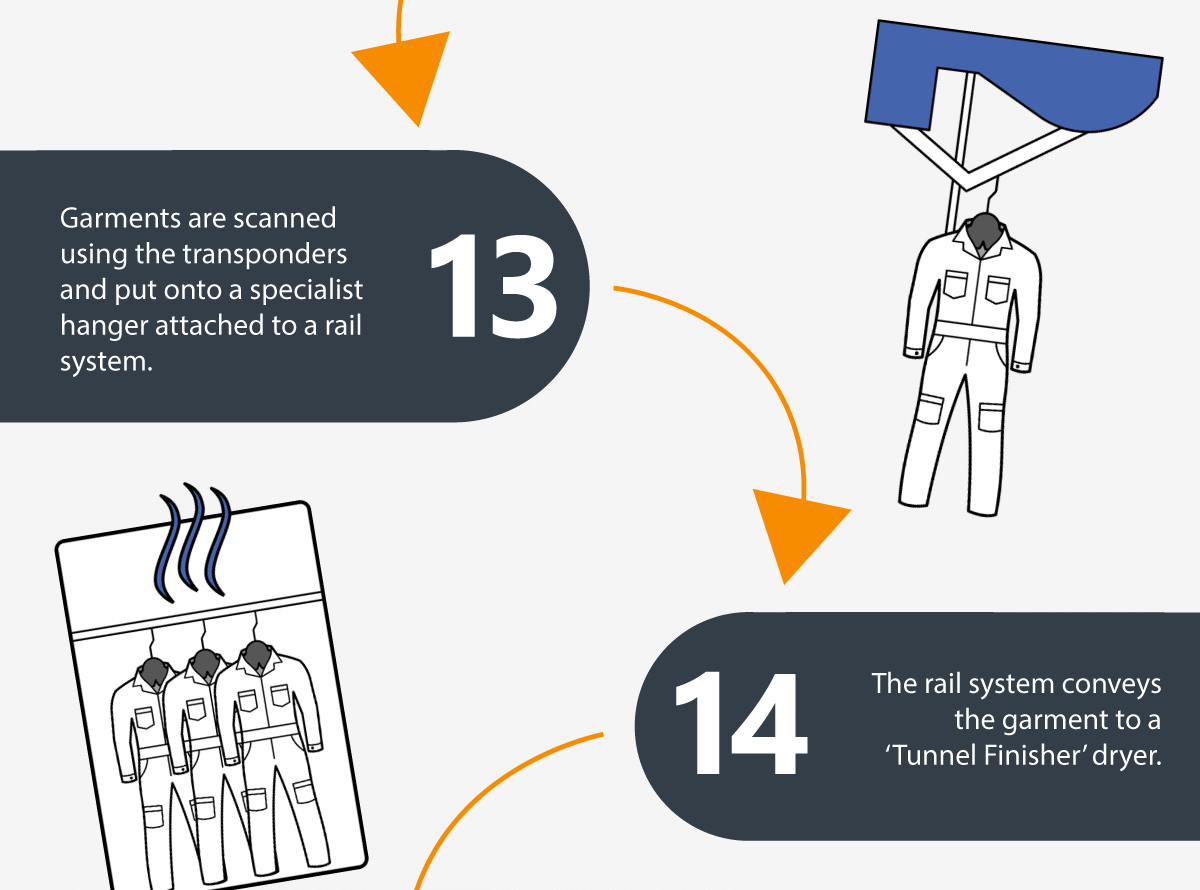

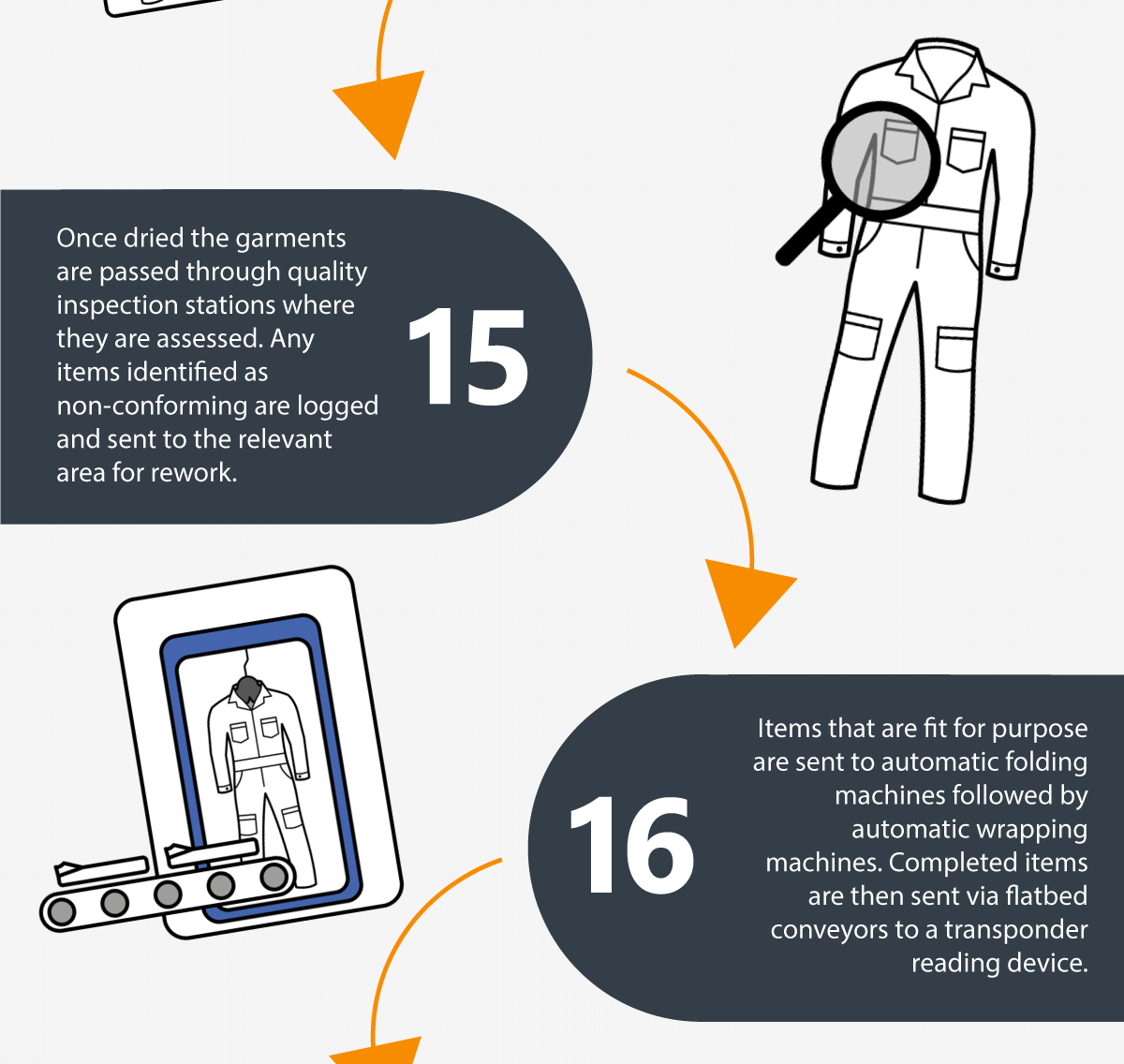

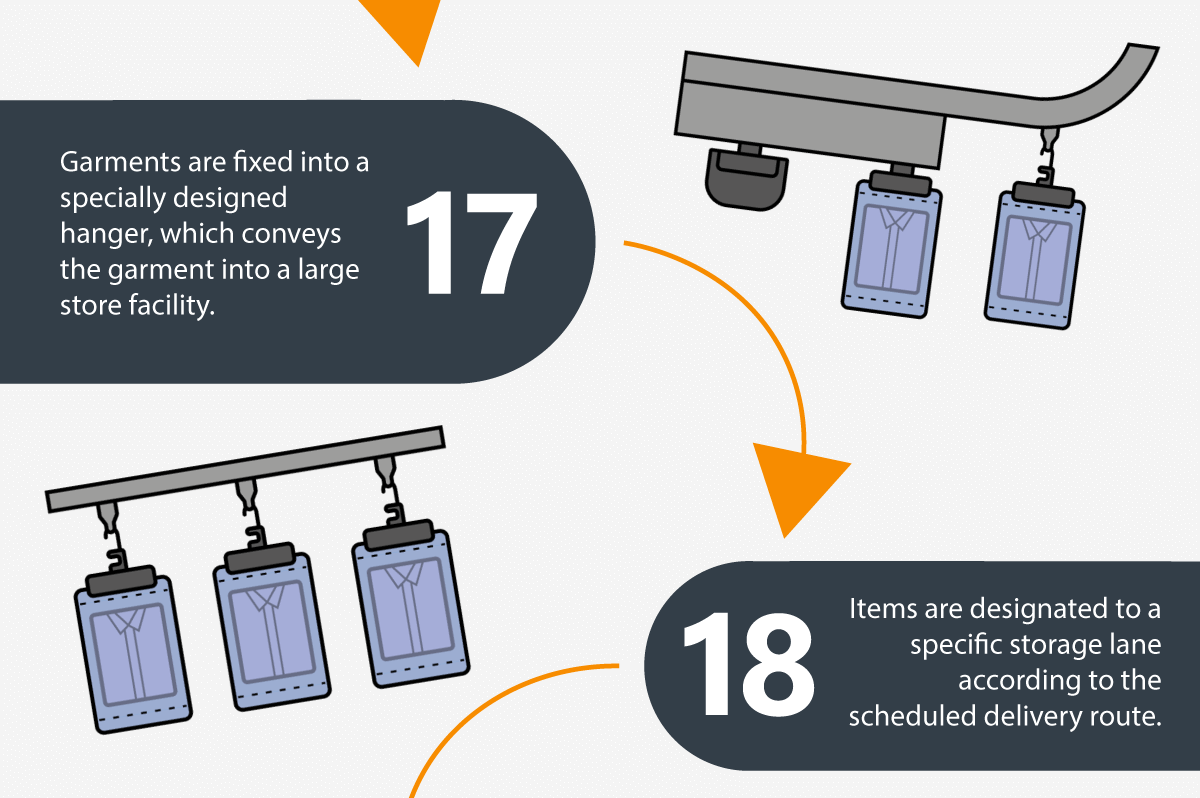

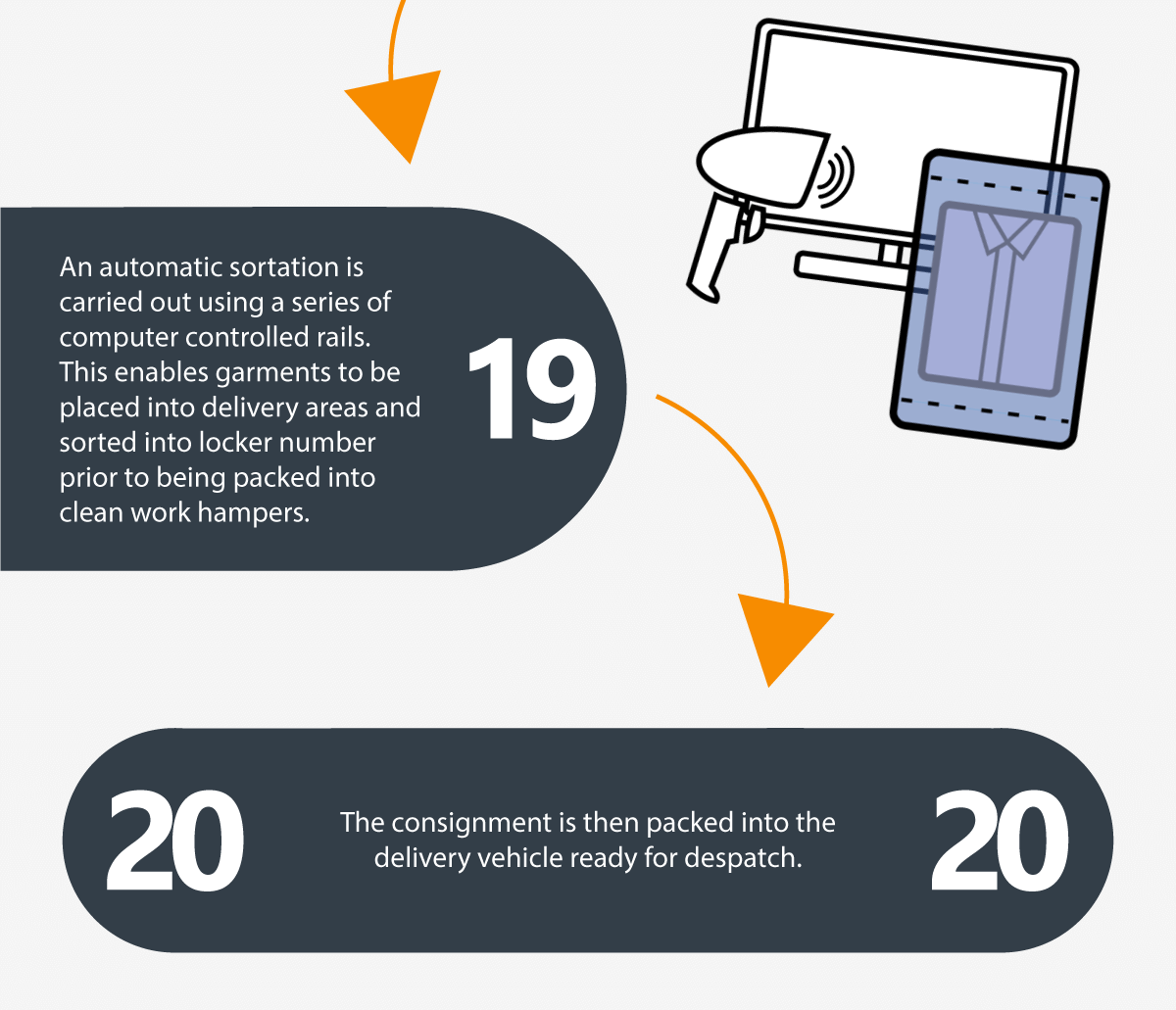

At Micronclean we use innovative ways to offer top quality services to our customers. A great example of this is our process flow for collecting, washing and returning paint shop garments using our ISO Class 6 cleanroom.