Technical Blog: Reusable versus Disposable Garment

BlogCleanroomPPE/TextilesSustainabilityMicronGreen12.02.2024

BlogCleanroomPPE/TextilesSustainabilityMicronGreen12.02.2024

The primary purpose of a cleanroom garment is that it must act as an effective contamination control measure, containing the viable and non-viable particulate released from the wearer and so preventing cleanroom contamination.

As a result, two of the key decisions facing the people operating a cleanroom in terms of garment choices are:

- Does my chosen garment system prevent cleanroom contamination? and

- What is the environmental impact of my choice?

Proving Garment Life

Over the past few years Micronclean has conducted extensive testing of its cleanroom garments to ensure that they exceed the requirements of GMP Annex 1 which are:

- All clothing and its quality should be appropriate for the process being undertaken, the grade of cleanroom and should always protect the product from contamination.

- Reusable cleanroom garments should undergo qualification studies which determine the life of the garments.

- Any garment testing should go beyond visual inspection, as this might not detect all the sources of damage that could affect the garments performance within the cleanroom.

The full results of the Micronclean testing programme can be found in a peer reviewed scientific journal (EJPPS) or as a document downloadable from our website (Link to PDF).

The conclusion of our research is that the Micronclean sterile cleanroom garments have proven contamination control performance in excess of the fifty process cycles limit of decontamination/drying/sterilisation/wearing at which we normally withdraw garments.

Environmental Impact Assessment

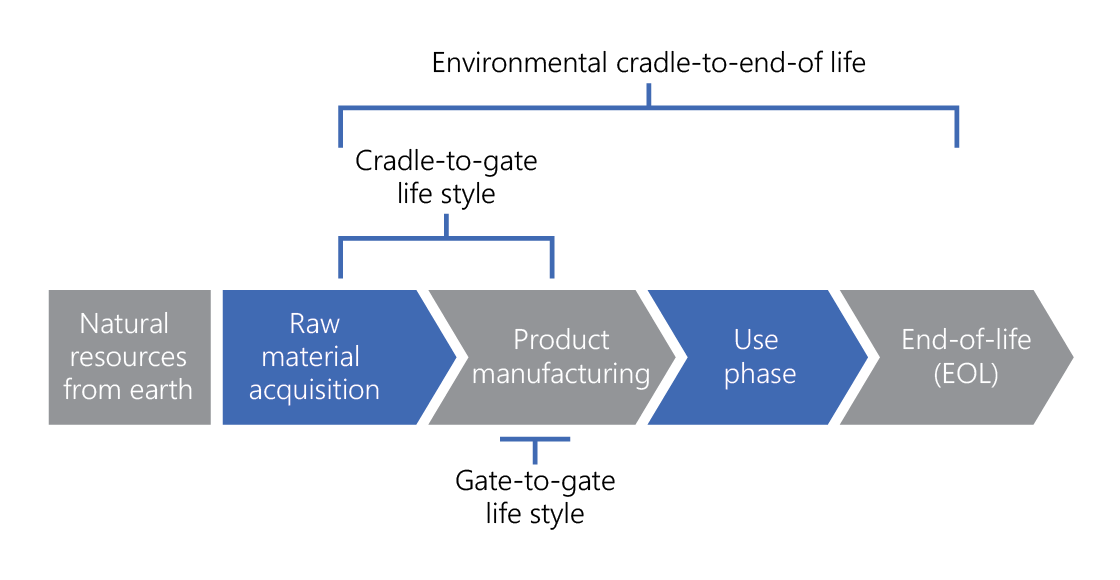

If we take the proven Micronclean fifty process cycle life expectancy of a reusable cleanroom garment as a base point, we can compare it with fifty single use disposable garments. In this way we can make sensible environmental comparisons between their competing "cradle to end of life" (CTEOL) performance (see Vozzola, E et al 2018 and Overcash M et al 2022).

Figure 1: Life Cycle Scope for Product Analysis.

Figure 1: Life Cycle Scope for Product Analysis.

The key stages for a complete CTEOL analysis are shown schematically in Figure 1 and show that it includes:

- Raw Material Acquisition

- Product Manufacturing

- Use Phase (including for reusable garments the reprocessing and transport steps) and

- End of Life

For the CTEOL comparisons the reusable coverall was taken as a being manufactured from a woven polyester fabric which is what the Micronclean reusable garments are made from. While the disposable gowns were assumed to be manufactured from a non-woven polypropylene fabric which is typical of cleanroom disposable garments in the marketplace.

The results of these CTEOL studies show that using a validated reusable system rather than a disposable garment system generates significant environmental benefits which can be summarised as:

- A 58% reduction in carbon footprint.

- A 59% reduction in process energy.

- A 77% reduction in water footprint.

- A 93% reduction in solid waste to landfill.

Of course, if the validated garment life is extended as is the case at our facility in India which uses an autoclave terminal sterilisation process, then the benefits continue to increase.

Conclusion

There is no denying that single use disposable garments have a very small place in the marketplace especially if linked to the use by isolated visitors to the cleanroom, where there is a specific need for chem splash type protection or where there is no viable reusable garment option.

However, the conclusion of our extensive garment testing is that Micronclean sterile cleanroom garments have proven contamination control performance in excess of the fifty process cycles limit of decontamination/drying/sterilisation/wearing at which we normally withdraw garments.

This means that if you consider a CTEOL analysis over fifty process cycles a validated Micronclean reusable garment system generates major environmental benefits compared to a disposable option which can be summarised as:

- A 58% reduction in carbon footprint.

- A 59% reduction in process energy.

- A 70% reduction in water footprint.

- A 93% reduction in solid waste to landfill.

Author

Stella Yates

Group Product Manager - Cleanroom Textiles

References

Vozzola, E.; Overcash, M.; Griffing, E. Life Cycle Assessment of Cleanroom Coveralls: Reusable and Disposable. PDA J.Pharm. Sci Technol. 2018, 72, 236-248

Overcash, M.; Griffing, E. National Economic and Environmental Benefit of Reusable Textile in Cleanroom Industry. PDA J.Pharm. Sci Technol. 2022, 76, 109-119